Bringing Once Invisible Particle Contaminants Into Sight

By Mikael Reimers, The Food Radar

A new technology is helping protect the quality of food products while maintaining control over manufacturing processes

Everyone — the consumer, the retailer, and the producer — loses when food is contaminated with foreign bodies. Although detection technologies have come a long way during the last few years, low-density foreign bodies such as plastic, wood, fruit stones, and lumps of starch are still invisible to all traditional detection systems. This very real threat to your customers, and to your business, makes this no laughing matter.

The Food Radar is the latest weapon in the arsenal of food safety technology. The product is essentially a sensor system designed for emulsions and pump-able products such as baby food, yogurt with berries, spreads, or tomato-based products. The system has the ability to detect not only dense foreign bodies — metal, stone, and glass — but is specifically designed to detect low-density contaminants such as wood, plastic, rubber, extraneous vegetable matter, and even insects.

Low density foreign bodies such as pit fragments, plastic foil, rubber, hard plastic, soft plastic, silicone and wood

Insects!

Creepy-crawlies aren’t nice, even when they’re dead. They’re especially unpleasant when they end up in consumables. Up until now, bugs have gone undetected by traditional food contaminant detectors. The new system is able to detect insects in products such as fruit spreads and preps. However, the insect must be hard-shelled — bees, wasps, beetles — to be found. Soft creatures — caterpillars, slugs, and larvae — still remain undetectable by the detection system as they are too similar in consistency to the product to be found.

|

|

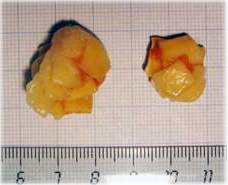

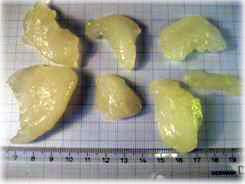

| Pasta boiled together, rejected in a baby food process | Lumps of starch rejected in a baby food process |

Product quality and manufacturing process control

In addition to the usual foreign bodies and particle contaminants, the Food Radar is able to detect extraneous organic matter. Products with organic defects such as lumps of starch, hunks of spices, and collected pieces of pasta or rice can be stopped early in the production process without damaging a brand in the supply chain through costly recalls and maddening complaints. This gives a new dimension to foreign body management. The technology can help safeguard the quality of product and the control over your manufacturing process.

Want to learn more about this new technology in particle contamination detection? Be sure to visit http://www.foodradar.com/