ABOUT US

You can depend on Thermo Scientific product inspection systems to provide you with the performance and service you need to improve the quality and safety of your packaged food products. We can help you eliminate errors, increase throughput, ensure the integrity of your brand and protect your profits. Deep applications expertise and customer service round out our package. Our product technologies include x-ray inspection , metal detection and checkweighing equipment solutions for food and beverage manfacturers.

INFOGRAPHICS

- 10 Tips For Top Checkweigher Performance

- Is X-Ray Inspection Of Packaged Food Safe?

- 5 Needed Inspection Points During Baked Goods Production

- 10 Ways To Save Money Using Checkweighing

- 10 Factors To Consider When Choosing An X-Ray System

- 5 Tips To Ensure Consistent Detection From Your X-Ray Equipment

- 5 Features To Consider When Selecting Bulk X-Ray Equipment

- Is Your Checkweigher A Millennial Or Baby Boomer

- 10 Tips To Assure Long-Term Success With A Metal Detector

CONTACT INFORMATION

Thermo Scientific Product Inspection

501 90th Ave NW

Minneapolis, MN 55433

UNITED STATES

Phone: 800-227-8891

Contact: Sales

E-BOOKS

-

Detecting physical contaminants in food, such as metal, glass, stone, plastic, and bone is like trying to find a needle in a haystack, especially when the contaminant may be as small as 1 mm in diameter. Metal detectors and X-ray detection systems provide the highest sensitivity so you can find virtually any foreign object in your packaged food products.

-

Nothing saves money like a checkweigher. It weighs every product in motion to. A checkweigher weighs every product in motion to help you meet throughput and legal requirements. Learn more about the technology and options for your application.

WHITE PAPERS

-

Learn more about these advanced product inspection technologies like metal detectors, X-ray systems, and checkweighers that are revolutionizing food safety and compliance.

-

One of the fastest growing areas of innovation in the food industry is plant-based proteins. Learn about this trend and how product inspection programs can adapt.

-

Consumer safety has always been a primary concern for food processors. HACCP (Hazard Analysis and Critical Control Points) has been a methology recommended by the FDA since the 1950s and food producers have always been conscious of their brand’s protection. The recent enactment of the U.S. Food Safety Modernization Act (FSMA) has turned the intensity up even higher.

-

Foreign objects such as small, oblong metal pieces like wires and pins exhibit “orientation effect,” a phenomenon in which the signal the metal detector sees is largely dependent on the contaminant’s alignment in relation to the detector’s aperture.

-

With nuts, seeds, dried fruits and dozens of other fresh, bulk food products are fetching sky-high prices of late due to demand and supply issues growers and producers need reliable ways to maximize production while eliminating contaminants. Gone are days of error prone human inspection or wasteful processes such as discarding partially clean products to avoid further inspection costs.

-

Some food manufacturers have lingering worries about the safety of X-ray technology – both for those operating the equipment and the food products the machines inspect. This paper takes a closer look at how today’s X-ray inspection equipment works and corrects any misconceptions associated with this commonly used technology.

-

This paper will examine foreign object detection in adulteration events, including the detection challenges of finding very small contaminants, in a complex and fast-moving, global supply chain.

-

Metal detectors in food processing have always had limitations. But, the technology is evolving and making food safer. This white paper offers guidance to help achieve 100 percent metal-free products.

-

Dairy products necessitate a high level of quality control and adherence to regulations. Fortunately, inspection technologies help keep dairy products safe and within product specifications.

-

With ingredient costs rising, it’s critical to minimize product give away. This paper discusses advanced checkweighing technology and how it ensures over/under-filled containers don't reach the marketplace.

-

Making sure final product weight is within acceptable min/max ranges is a critical manufacturing objective for F&B companies. This article details how checkweighers help ensure proper fill levels.

-

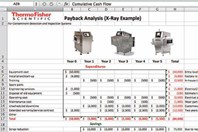

Contaminants are a fact of life for food manufacturers, making contaminant detection systems a necessity. This article explains the process of calculating the ROI of foreign body detection systems.

-

Metal detection and X-ray inspection, traditionally, have been the first line of defense to identify foreign contaminants in food. For food quality and safety professionals, choosing a detection system is typically based on three things: the optimum detection point, overall application capability, and total cost/benefit. However, engineering and software improvements continue to set new standards of detection. This has led to some confusion regarding which technology to employ and why. This white paper intends to clarify which inspection technology will most benefit your company.

-

Contaminants are a fact of life for food manufacturers, making contaminant detection a necessity. This five-step process is one way to calculate the payback of purchasing contaminant detection systems.

-

Checkweighers are key to measuring efficiency and cost of a packaging line. However, there are factors that may require customization that play a role in the success of your checkweigher.

-

Nuts, seeds, dried fruits and dozens of other fresh, bulk food products are fetching sky-high prices of late due to demand and supply issues caused by the drought in California. Consequently, this brings the need for reliable ways to maximize production while eliminating contaminants. This requires extra diligence, including the use of advanced inspection equipment to remove foreign objects. Gone are days of error prone human inspection or wasteful processes such as discarding partially clean products to avoid further inspection costs.

-

Evolving inspection/detection technology can help both baking and snack food companies get their products to market contamination-free and in the case of multiple-item packs, with all of the promised pieces in place. Using inline checkweighers to weigh packaged products ensures that they contain the correct amount of expensive product ingredients and that dispensing equipment is operating correctly. This aids in problem identification and facilitates uptime on today’s high-rate lines.

-

Unlike the traditional and manual ‘three metal pass/fail’ system auditing, this new technology can detect potential problems before there is a failure during a manual audit, thus limiting expensive downtime and repair costs. It can also decrease or even eliminate the time and energy spent manually auditing and recording the food metal detector’s results — thus improving overall production efficiency. Moreover, it can help food manufacturers achieve the highest food safety standards. This paper explains how the performance verification system option works and why it can augment or replace manual auditing.

-

X-ray inspection in food processing lines can provide many benefits you may be unaware of. Here are 10 reasons to consider stepping up to the latest technology utilized in X-ray inspection systems.

-

Learn about a unique performance verification system that utilizes an automated test shuttle that moves through the metal detector’s field at user-specified points in time.

VIDEOS

-

Watch to explore the various types of reject devices and their specific uses and gain insights to help you make well-informed choices for your quality control processes.

-

Watch to gain insight into the crucial role of maintenance in ensuring the ongoing optimal performance, reliability, and longevity of your inspection systems.

-

Explore key considerations for inspection at the raw material stage as well as food safety inspection technologies that can be applied in this early step in the food manufacturing process.

-

A holistic product inspection plan can help companies seize the highly profitable and rapidly growing business opportunity of quick-prep foods and meal kits while ensuring food safety and brand protection.

-

Explore foreign object detection technologies and their respective capabilities in detail to learn which may be most appropriate for your individual product, packaging, and processing requirements.

-

Explore the challenges in inspecting a wide range of pet foods and package types for foreign objects as well as technology considerations for critical control points.

-

In this video presented at Pack Expo Connects, discover how our new Sentinel metal detection technology platform can enable you to have a higher level of brand protection. See both the Sentinel 1000 single-frequency Selectscan metal detector and the Sentinel 5000 five-frequency Multiscan metal detector in action.

-

In this video presented at Pack Expo Connects, see our latest combo system technology in action. Learn the five reasons that a combination system using our Sentinel metal detection technology platform can help improve food safety, brand reputation and your process.

-

In this video presented at Pack Expo Connects, see how the Thermo Scientific NextGuard X-ray Inspection system can support your food safety and quality goals and how its novel design expands the probability of detecting foreign objects. NextGuard is an ideal choice for making the transition from metal detection to X-ray inspection easy.

-

Thermo Scientific product inspection solutions including a new technology platform for metal detection support Cedars Mediterranean’s food safety program, which is integral to delivering quality products for consumers. See the technologies in action and learn about the company’s commitment to quality.

-

A combination system featuring a Thermo Scientific Sentinel 3000 Multiscan Metal Detector and a Thermo Scientific VersaWeigh Checkweigher provides five-frequency metal detection along with a harmonized version of checkweigher software for ease of use. Watch this video for more about this combination system with our best metal detection and weighing technologies.

-

In this short video you’ll learn about the rigorous product test process at Thermo Fisher Scientific.

-

See everything you can learn from the detailed product test results and what they may mean for your food safety.

-

Watch this short demo and discover what you might be missing with only one to two frequencies in multi-frequency metal detection.

-

Get to know Thermo Fisher Scientific Product Inspection business and how we can help support the quality and safety of your products.

-

Overview of the new technology platform for Thermo Scientific metal detectors.

-

When you suspect physical contaminants in your packaged products, turn to Thermo Scientific’s confidential service to identify and isolate problems fast. Our highly experienced staff uses the most advanced Thermo Scientific X-Ray, Metal Detection, and Checkweighing systems to thoroughly test every package to help maximize the recovery of in-spec products for distribution and eliminate defective products.

-

Cedar’s Mediterranean Foods has been a long time user of Thermo Fisher Scientific’s inspection equipment. Using metal detectors and checkweighers at their level 3 Safe Quality Food certification site, enables them to provide a safe and consistent quality product to their customers, while optimizing their production throughput.

-

Caribou Coffee trusts Thermo Fisher Scientific’s quality control tools to guarantee that customers get the same amazing cup of coffee they expect each and every time. From the consistent accuracy of our checkweighers, to the detection performance of our X-ray systems, our solutions are proven effective and expertly tailored to Caribou Coffee applications.

-

The Thermo Scientific™ Xpert™ Bulk X-ray Inspection Systems start where other contaminant detection approaches leave off. They are ideal for finding metal, glass, rock and other objects in bulk foods such as nuts, seeds, berries or vegetables. The systems come in two inspection widths to optimize throughput/cost and can be customized to fit your production environment.

-

Family-owned Catallia Mexican Foods turned to Thermo Fisher Scientific to help manage underfills and overfills of its packaged tortilla products. The Thermo Scientific Versa Flex Checkweigher for dry applications was the right solution, enabling Catallia to drive out variability and drive up ROI.

-

Maximize profits and minimize product giveaway with the Thermo Scientific™ Global VersaWeigh™ Checkweigher. This versatile, scalable system is still easy-to-use and maintain but now features more than 10 engineering and functionality improvements including frames designed to reduce food buildup, rapid-release, adjustable conveyors and belts, and high-torque sealed brushless motors for trouble-free operation. The fixed-height Global VersaWeigh is ideal for products up to 10 kilograms (22 pounds) and performs with an accuracy equal to or better than market requirement standards.

-

The APEX HD metal detector is designed to withstand rugged use and harsh washdown with caustic chemicals.

-

Nothing saves money like a checkweigher. The Thermo Scientific™ Global VersaWeigh™ and Global Versa GP checkweighers have many engineering and functionality improvements to help you gain better control of your process. Reduce giveaway, decrease maintenance costs and reduce total cost of ownership.

-

The newest innovation in product inspection, Thermo Scientific's NextGuard X-ray Detection System

-

The Thermo Scientific Xpert X-ray Inspection System has high resolution and sensitivity and can find contaminants other systems miss. Ideal for food and beverage industry with emphasis on products that contain metalized film or wrapping.

-

The Thermo Scientific Xpert X-ray system has high resolution and sensitivity and can find contaminants other systems miss.

-

To address the TCO (Total Cost of Ownership) of X-ray systems the Xpert system minimizes training, a five-step, Easy Set-Up process was created and a simplified, password protected operator interface was designed.

-

The Thermo Scientific Xpert inspection system enables compliance with worldwide HACCP and retailer food safety requirements as well as IP65 compliant in accordance with IEC 60529 and EN 60529.

-

The new Versa Warehouse software for improved accuracy and reliability of the warehouse in-line scale.

-

The Thermo Scientific APEX 100 metal detector provides protection from many types of metal contaminants encountered in food production today.

-

Discover the current regulatory framework and how product inspection technologies can help compliance, driving increased levels of food safety, consumer protection and operational efficiency.

-

Learn how Thermo Scientific product inspection systems help customers rapidly identify and correct problems in food and pharmaceutical packaging.

-

There are contamination risks from multiple sources throughout the whole food supply chain. Discover how modern product inspection techniques can help reduce brand vulnerability to unwanted contamination escapes.

-

Learn how to kick the product inspection challenges of product and package effect to detect foreign objects and contaminants, keep consumers safe, and protect your brand image.

-

Explore the factors to consider when weighing the options and the range of technologies available to meet your quality, production, and ROI requirements.

-

The past few years have seen a continuing trend towards healthy eating in many global regions, accelerated by the COVID-19 pandemic. People are looking to boost their immune systems and health with better food choices. The fresh fruits and vegetables market has seen above market average growth and it is expected to continue. Fruit and vegetable processors need to respond to this increased demand without compromising on product quality and safety. Discover how the latest product inspection technologies can support growing production quotas while maintaining safety, quality and plant efficiency.

NEWS & ARTICLES

- Enhance Accuracy And Efficiency In Lightweight Applications

- Ensuring Food Manufacturing Quality Assurance With Reject Devices

- The Significance Of Preventive Maintenance For Product Inspection Systems

- Artificial Intelligence (AI) In Food Production

- Ensuring High Quality And Contaminant-Free Pet Foods

- Best Practices To Avoid Metal Contamination In Candy Manufacturing

- X-Ray Inspection Vs. Metal Detection Technologies For Food Safety: What Should You Know?

- Are You Missing An Important Stage In Raw Material Product Inspection?

- How To Obtain Accurate Weight Measurement In Cheese Products

- Why The Sudden Rise In Metal Contaminants In Food Manufacturing?

- Raw Material Product Inspection: Are You Missing This Important Stage?

- Overcoming Key Inspection Challenges For Quick-Prep Foods And Meal Kits

- Metal Detection Or X-Ray Inspection: Which Is Right For Your Application?

- Product Inspection Insights For Pet Food Safety And Quality

- Detecting Required Metallized Components' Presence In Food Products

- Enhanced Metal Detector Performance For Conductive Products

- High Accuracy And Speed Inline Checkweighing For Industrial Cheese Making

- A Practical Guide To Metal Detection And X-ray Inspection Of Food

- Assuring The Safety Of Frozen Foods During A Global Pandemic

- New Metal Detector Enhances Foreign Object Identification For Food Processors

- Achieve A Higher Level Of Food Safety With Selectscan Metal Detection

- A Practical Guide To Checkweighing And Checkweighers

- Foreign Object Detection Challenges In Meat Processing

- New Metal Detection System Designed For A Wide Range Of Food Applications

- Foreign Object Detection Compliance With Food Retailer Codes Of Practice

- Eliminating Metal Foreign Object Escapes With Multiscan Technology

- New Software Technology Improves Metal Detection Capabilities In Cheese Applications

- What Is The Optimum Detection Point During Food Inspection?

- Verification Steps To Test Metal Detector Failure

- Is There Foreign Material In Your Finished Product?

- Inspecting Snack Foods Through Metalized Film Packaging

- How To Beat The Challenge Of Bread's Physical Properties During Inspection

- Does Food Packaging Matter?

- Product And Contamination Inspection For The Meat , Poultry, And Seafood Industries

- 10 Facts Food Processors Need To Know Before Deploying X-Ray Inspection

- Product Inspection: Current Challenges And Future Outlook

- Assuring Food Safety: Metal Detection Versus X-Ray Inspection

- Fresh Fruits & Vegetables - Meeting Increasing Consumer Demand

- Reducing Vulnerability To Foreign Object Contamination In The Food Processing Industry

- How A Checkweigher Can Address Track And Trace Requirements For ePedigree Compliance

- Gaining An Edge – The Value Of Exceeding Regulatory Standards In Food Manufacturing

- Metal Detectors And X-Ray Inspection Systems: What You Need To Know

- New Software Technology Improves Metal Detection Capabilities In Cheese Applications

- How X-Ray Inspection Ensures The Safety Of Dairy Products

- Ensuring Food Safety And Brand Protection For Pet Food Products

- Top Considerations Of In-Line Checkweighers In A Manufacturing Process